PCBA

New Flairs In Global Application Of LED Lighting With The PCB Manufacturing

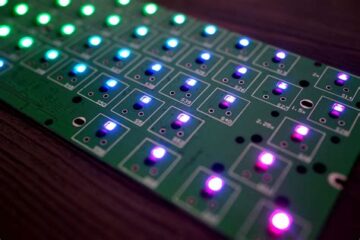

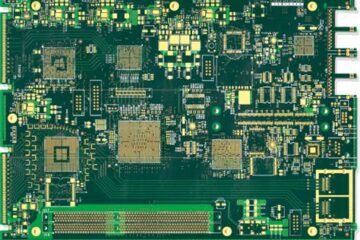

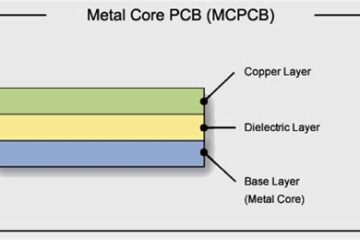

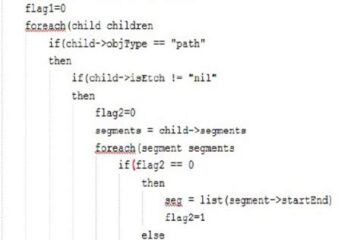

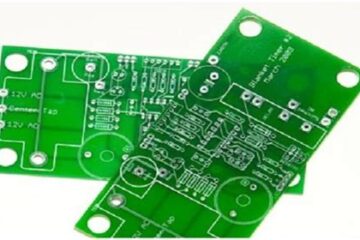

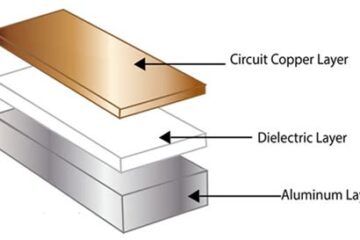

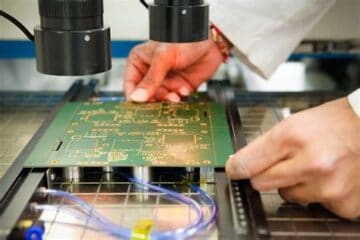

Introduction to LED PCB Light-emitting diode (LED) technology has revolutionized the lighting industry with its energy efficiency, durability, and versatility. The core of LED lighting lies in the printed circuit board (PCB) manufacturing process, which plays a crucial role in the performance and reliability of LED lighting systems. LED PCBs are specially designed to provide optimal thermal management, electrical conductivity, and mechanical support for LED components. In recent years, the global application of LED lighting Read more…