PCBA

FLYING PROBE TEST

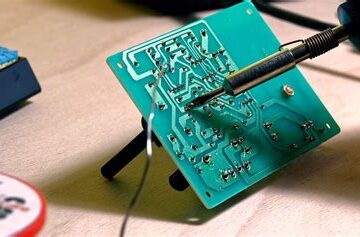

What is Flying Probe Test (FPT)? Flying Probe Test (FPT) is an advanced method for testing printed circuit boards (PCBs) without the need for a custom test fixture. Unlike traditional bed-of-nails testing, which requires a unique test fixture for each PCB design, FPT utilizes movable probes that can be programmed to test any point on the board. This flexibility makes FPT an ideal solution for low-volume production, prototyping, and high-mix manufacturing environments. How Flying Probe Read more…