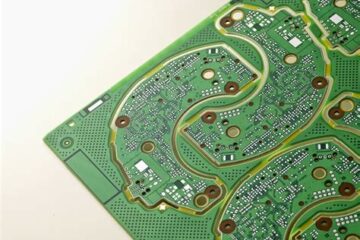

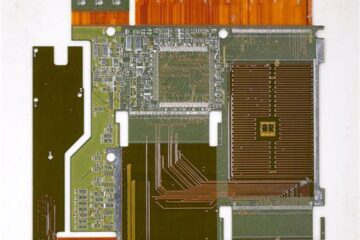

PCBA

Enhance the Quality of PCB Fabrication with HDI PCB Technology!

What is HDI PCB Technology? HDI PCB technology is an advanced PCB manufacturing process that allows for the creation of high-density interconnects on a printed circuit board. It involves the use of microvias, which are small holes drilled in the PCB to connect different layers, enabling more compact and complex designs. HDI PCBs typically have a higher wiring density and smaller feature sizes compared to traditional PCBs. Key Features of HDI PCBs Microvias: HDI PCBs Read more…