PCBA

PCB X-ray Inspection: The Importance of X-ray Inspection in PCBA

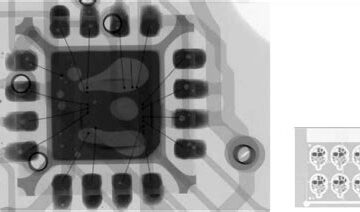

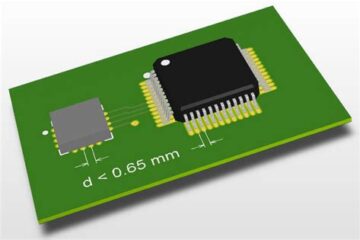

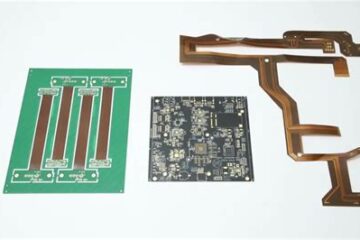

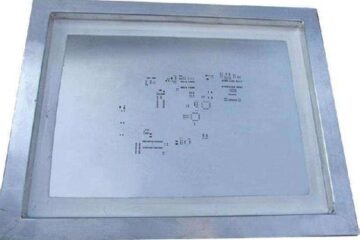

What is PCB X-Ray Inspection? PCB X-ray inspection is a non-destructive testing method that utilizes X-ray technology to examine the internal structure of an assembled printed circuit board. By passing X-rays through the PCB, manufacturers can create detailed images of the board’s components, solder joints, and other critical features. These images allow for the detection of defects and anomalies that may not be visible to the naked eye or through other inspection methods. How PCB Read more…