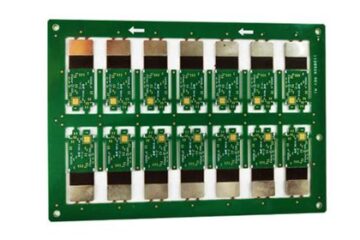

PCBA

Surface Mount-Types of SMD(Surface Mount Device) Packages

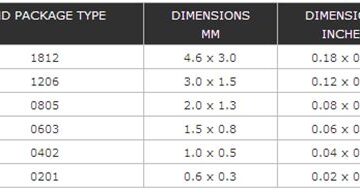

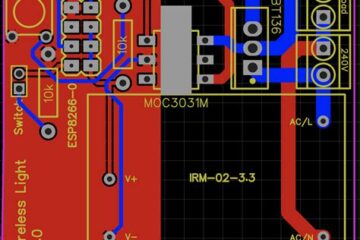

Introduction to SMD Packages Surface Mount Devices (SMDs) have revolutionized the electronics industry by enabling the miniaturization of electronic components and the development of high-density printed circuit boards (PCBs). SMD packages come in various shapes, sizes, and configurations to accommodate different component types and application requirements. This article explores the most common types of SMD packages, their characteristics, and their applications. Request PCB Manufacturing & Assembly Quote Now What are SMD Packages? SMD packages are Read more…