PCBA

Flexible PCB Market to Reach USD 27.6 Billion by 2024

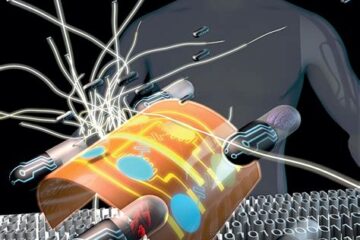

What are Flexible PCBs? Flexible PCBs, also known as flex circuits, are thin, lightweight, and flexible printed circuit boards that can be bent, twisted, or folded to fit into compact spaces. They are made of a flexible substrate, such as polyimide or polyester, and are designed to provide electrical connectivity between various components in electronic devices. Flexible PCBs offer several advantages over traditional rigid PCBs, including: Reduced weight and size Improved reliability and durability Enhanced Read more…