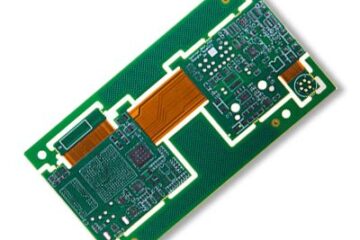

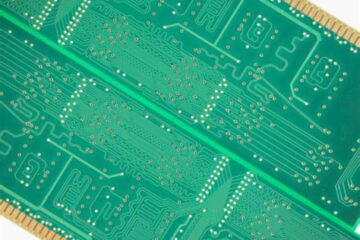

PCBA

What are Copper Clad Laminates?

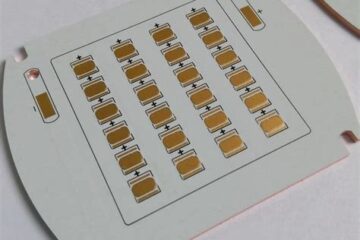

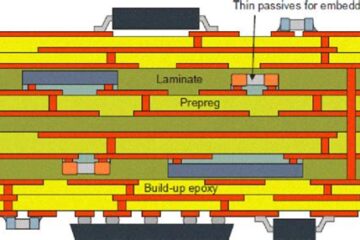

Types of Copper Clad Laminates There are several types of Copper-Clad Laminates available in the market, each with its unique properties and applications. The most common types include: FR-4 Laminates FR-4 (Flame Retardant 4) is the most widely used copper-clad laminate in the PCB industry. It consists of a woven fiberglass cloth impregnated with an epoxy resin. FR-4 laminates offer excellent mechanical strength, thermal stability, and electrical insulation properties. They are suitable for a wide Read more…