PCBA

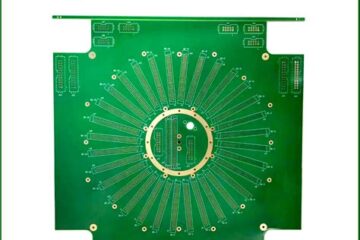

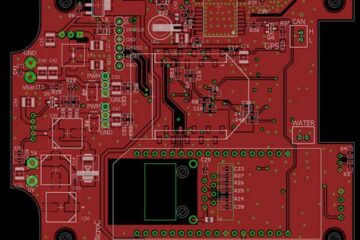

What are PCB Gold Fingers?

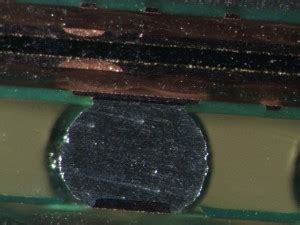

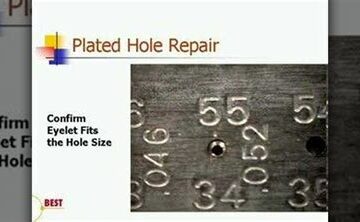

What are Gold Fingers Made Of? Gold fingers are typically made of copper, which is then plated with a layer of nickel and a final layer of gold. The copper provides excellent electrical conductivity, while the nickel layer acts as a barrier to prevent the copper from diffusing into the gold layer. The gold plating ensures a corrosion-resistant, durable, and highly conductive surface for reliable electrical contact. The thickness of the gold plating is usually Read more…