PCBA

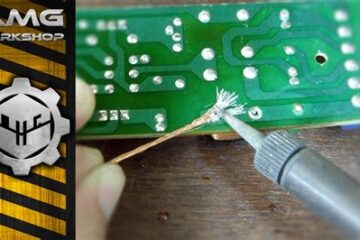

What are Lifted Pads on Printed Circuit Boards?

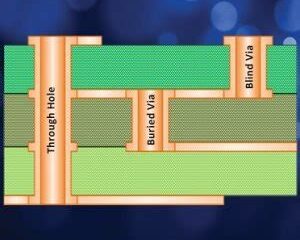

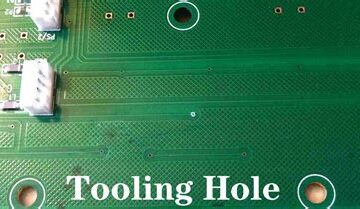

What Causes Lifted Pads on PCBs? There are several potential causes of lifted pads on printed circuit boards: Incorrect Hole Drilling One common cause is incorrect hole drilling during PCB fabrication. If the holes for through-hole components or vias are drilled off-center from the pads, there will be less bonding area between the pad and board. This makes the pad-to-board adhesion weaker and more prone to lifting. Recommended drill hit location: Pad Size Ideal Hit Read more…