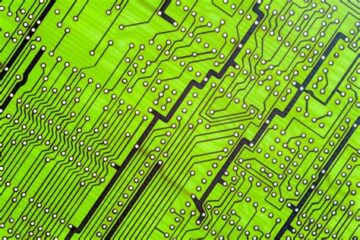

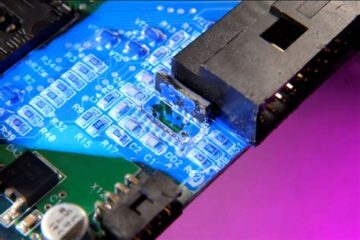

PCBA

What is ENEPIG Plating?

What is ENEPIG Plating? ENEPIG is a type of surface finish that consists of three layers: electroless nickel, electroless palladium, and immersion gold. These layers are deposited onto the copper pads of a PCB to protect the copper from oxidation and provide a reliable surface for soldering components. Layers of ENEPIG Plating Electroless Nickel (Ni): The first layer, typically 3-6 microns thick, serves as a barrier between the copper and subsequent layers. It prevents the Read more…