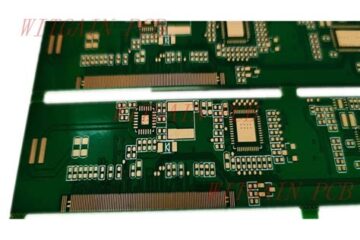

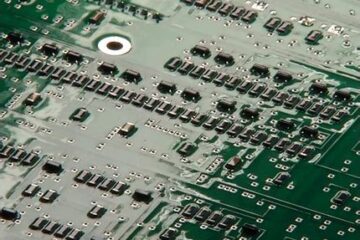

PCBA

What is Lead-based (non-RoHS) Soldering?

The History of Lead-based Soldering Lead has been used in soldering for centuries, with evidence of its use dating back to ancient civilizations. In the modern era, lead-based solders became the standard in the electronics industry due to their favorable properties, such as low melting point, good wettability, and excellent electrical conductivity. The most common lead-based solder alloy is known as Sn63Pb37, which consists of 63% tin (Sn) and 37% lead (Pb) by weight. This Read more…