PCBA

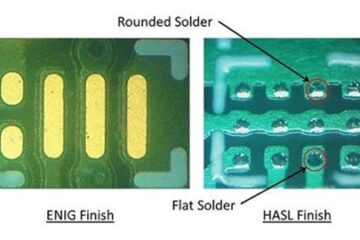

What is Hot Air Solder Leveling (HASL) PCB Surface Finish?

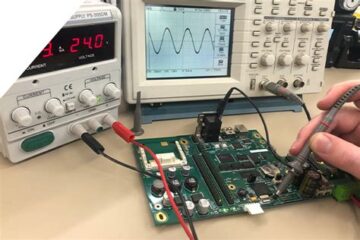

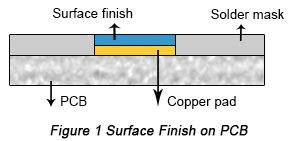

How HASL Surface Finish is Applied The HASL process consists of several steps to ensure a high-quality surface finish: PCB Preparation: The PCB undergoes a cleaning process to remove any contaminants or oxides from the copper surface. This step is crucial for achieving a uniform and adherent solder coating. Fluxing: A thin layer of flux is applied to the exposed copper pads to improve the wetting and spreading of the molten solder. The flux also Read more…