PCBA

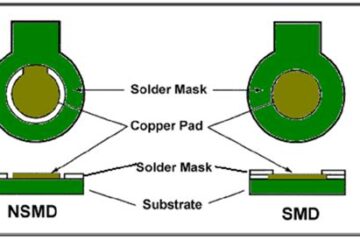

What is the Solder Mask?

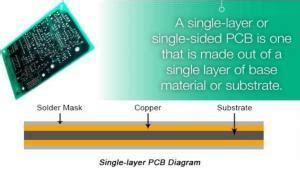

What is a Solder Mask Made Of? Solder masks are typically made of a polymer-based material, such as epoxy or acrylic. These materials are chosen for their excellent electrical insulation properties, durability, and resistance to heat and chemicals. The most common solder mask materials include: Liquid Photoimageable Solder Mask (LPSM): A photosensitive liquid polymer that is applied to the PCB and then exposed to UV light to cure and harden. Dry Film Photoimageable Solder Mask Read more…