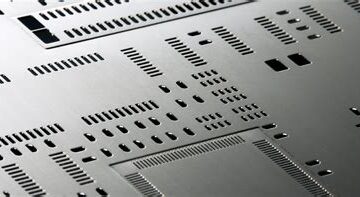

PCBA

The Disposal of Chemicals From PCB Etching

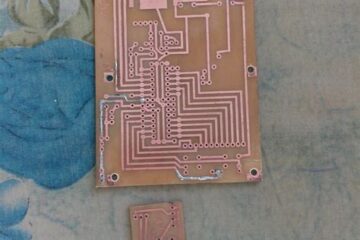

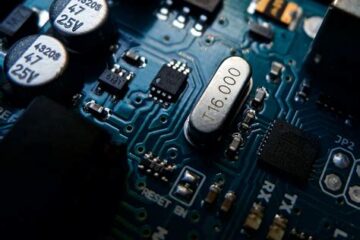

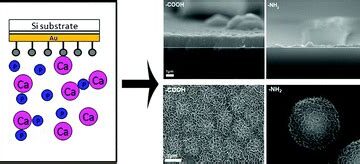

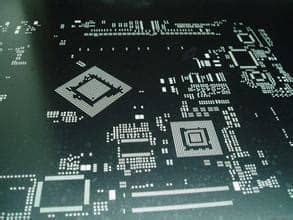

Introduction to PCB Etching and Chemical Disposal Printed Circuit Board (PCB) etching is a crucial process in the manufacturing of electronic devices. It involves the use of various chemicals to remove unwanted copper from the surface of the PCB, leaving behind the desired circuit pattern. While PCB etching is essential for creating functional electronic components, it also generates hazardous chemical waste that must be properly disposed of to minimize environmental impact and ensure the safety Read more…