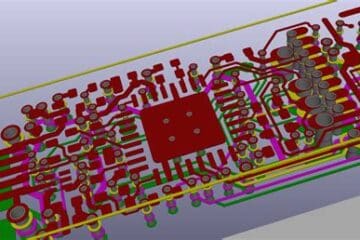

PCBA

PCB Design Companies that use Kicad

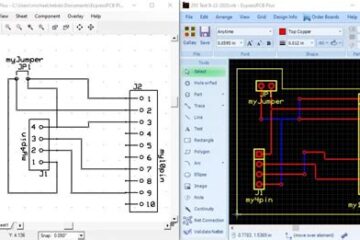

What is Kicad? Kicad is a free and open-source electronic design automation (EDA) software that enables users to design electronic schematics and PCBs. It is a cross-platform software that runs on Windows, macOS, and Linux operating systems. Kicad was developed by Jean-Pierre Charras and released under the GNU General Public License (GPL), which allows users to modify and distribute the software freely. Kicad consists of several tools that work together to create a complete PCB Read more…