PCBA

PCB Drawings: 5 Drafting Standards

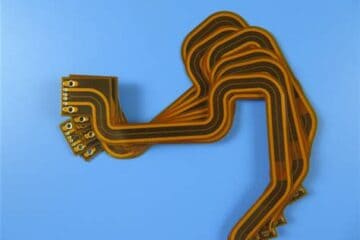

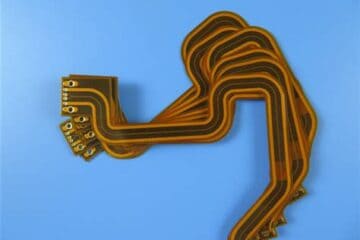

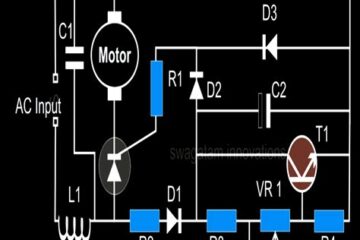

Introduction to PCB Drafting Printed Circuit Board (PCB) drafting is a crucial process in the design and manufacture of electronic devices. It involves creating detailed drawings and schematics that provide a clear visual representation of the PCB layout, components, and connections. Adhering to established drafting standards ensures that PCB designs are accurate, consistent, and easily understood by all stakeholders involved in the manufacturing process. In this article, we will explore five essential drafting standards that Read more…