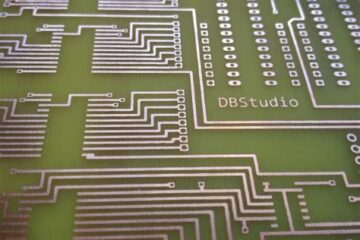

PCBA

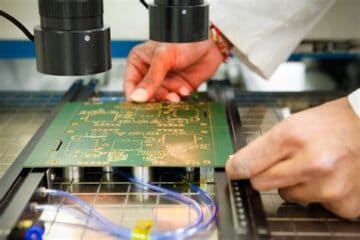

How to Build a Circuit Board- Key Steps to Making DIY Circuit Boards

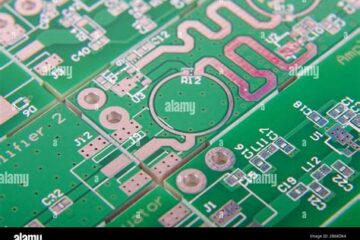

Understanding the Basics of PCB Design Before diving into the process of building a circuit board, it’s essential to understand the fundamentals of PCB design. A PCB is a flat board made of insulating material, such as fiberglass or plastic, with conductive traces printed on its surface. These traces connect various electronic components, forming a complete circuit. Types of PCBs There are three main types of PCBs: Single-sided PCBs: These boards have conductive traces on Read more…