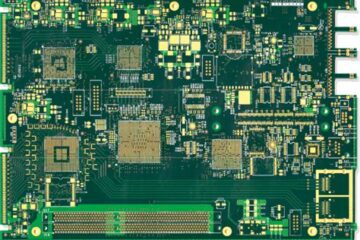

PCBA

How can the thermal dissipation be achieved for cooling?

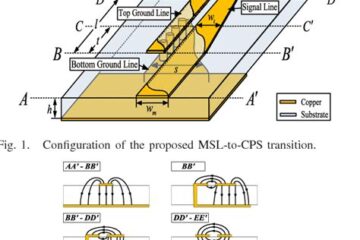

What is Thermal dissipation? Thermal dissipation refers to the process of transferring heat away from a heat source to the surrounding environment. This is essential for maintaining the temperature of the heat source within its optimal operating range, preventing overheating and potential damage. Thermal dissipation is achieved through various heat transfer mechanisms, including conduction, convection, and radiation. Conduction Conduction is the transfer of heat through direct contact between two objects or materials. In the context Read more…